Driving Sustainability: How PCBA Innovations are Shaping the Future of Eco-Friendly PCB Automotive Electronics

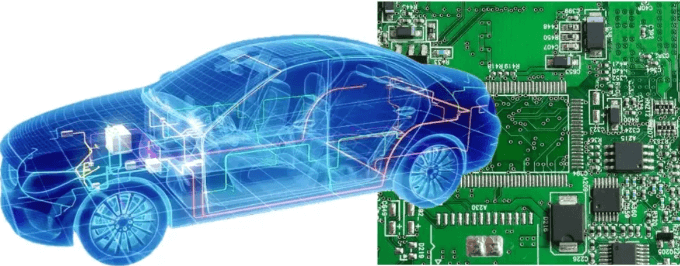

In today’s world, where the race toward sustainability is in full throttle, the automotive industry finds itself at a pivotal crossroads. With the increasing demand for electric vehicles, hybrid systems, and smarter technologies, one thing is clear: the future of transportation isn’t just about what powers the engine—it’s about the intricate electronics working behind the scenes. Enter PCBA (Printed Circuit Board Assembly) and PCB automotive innovations. They are improving modern cars and creating a new way of driving that is better for the environment.

PCBA: The Brains Behind Automotive Electronics

While the sound of an engine might be music to a gearhead’s ears, what’s really driving today’s cars are complex electronic systems. PCBA is the way electronics are put together. It includes everything from resistors to microchips. But here’s where things get interesting: modern PCBA technology is evolving rapidly, with a strong focus on sustainability.

From energy-efficient processors to low-power circuits, PCBA innovations are making cars smarter, greener, and more efficient. Automotive electronics today control everything from advanced driver-assistance systems (ADAS) to battery management in EVs. And the best part? They’re doing it in a way that reduces the overall environmental impact of the vehicle.

The shift toward PCB automotive designs that prioritize lightweight, efficient materials is leading to lower emissions and better fuel economy—not just in EVs but across the board. Whether you’re driving a hybrid or a gasoline-powered vehicle, PCBA is at the forefront of optimizing performance with sustainability in mind.

Driving Innovation: Eco-Friendly PCB Automotive Solutions

So, how does PCB automotive technology fit into the sustainability puzzle? The answer lies in the materials and manufacturing processes themselves. PCBs have traditionally been manufactured using processes that are not exactly eco-friendly, such as hazardous chemicals, energy-intensive production, and non-recyclable components. But times are changing.

New advances in PCB automotive technology are bringing sustainable materials like biodegradable substrates and energy-efficient manufacturing methods to the forefront. Flexible PCBs can help reduce waste and also handle heat better and last longer, which is important for vehicles that are often stressed.

Moreover, as automakers continue to demand smarter, lighter, and greener electronics, PCB manufacturers are rising to the challenge by adopting eco-conscious practices like waterless fabrication and energy-efficient soldering techniques. These advancements not only reduce the carbon footprint of the production process but also enhance the recallability of the final product. In short, we’re seeing a full lifecycle approach to sustainability, from manufacturing to end-of-life disposal.

PCBA’s Role in Electric Vehicles: Powering a Greener Future

As we look toward the future, there’s no denying the role of electric vehicles (EVs) in achieving sustainability goals. But what many might not realize is that PCBA technology is the linchpin holding the entire EV ecosystem together.

From battery management systems to motor controllers, PCBA designs are evolving to meet the rigorous demands of electric powertrains. Advanced PCBA systems are enabling more efficient energy use, longer battery life, and even faster charging times—all while reducing the environmental impact of the vehicle’s electronic components.

The result? Electric vehicles that not only have zero tailpipe emissions but are also powered by electronics designed with sustainability at their core. This is the future of PCB automotive, where performance and eco-friendliness go hand in hand.

Smart Cars, Smarter Choices: How PCBA Supports Sustainable Transportation

But it’s not just about EVs. Smart cars equipped with advanced PCBA systems are making transportation as a whole more sustainable. Features like regenerative braking, autonomous driving, and real-time energy monitoring all rely on sophisticated PCB automotive electronics to function seamlessly.

Think of the regenerative braking system, for instance: It captures energy that would otherwise be lost and channels it back into the vehicle’s battery. The entire system hinges on finely tuned PCBA boards that can process data in real-time while ensuring energy flows back where it’s needed most. This is a prime example of how sustainability isn’t just about cutting emissions—it’s about making the entire vehicle smarter and more energy-efficient.

And let’s not forget autonomous driving. As self-driving cars continue to evolve, PCBA will play an integral role in processing the vast amounts of data needed to navigate safely. These boards are responsible for powering sensors, cameras, and radar systems, each of which works in harmony to reduce accidents and improve fuel efficiency. Smarter roads, fewer accidents, and reduced traffic congestion—now that’s a sustainable vision we can all get behind.

Challenges and the Road Ahead: Navigating PCBA’s Sustainability Journey

Of course, no technology comes without its challenges. In the case of PCBA and PCB automotive innovations, one of the biggest hurdles remains the cost of adopting sustainable materials and processes. Eco-friendly substrates and energy-efficient manufacturing techniques often come with higher upfront costs. But as demand for greener technology rises, economies of scale will likely bring these prices down.

Another challenge is ensuring that sustainable PCBs can meet the rigorous durability and performance demands of the automotive sector. These circuits must operate under extremely harsh conditions, such as high temperatures, vibrations, and constant wear. Fortunately, ongoing research into materials like graphene and biodegradable polymers is showing promise in balancing sustainability with ruggedness.

Read also: The Quiet Tech Revolution in Schools: Why Interactive Displays Are the New Must-Have Tool

Conclusion: The Road to a Greener Tomorrow

As the world shifts gears toward sustainable, the automotive industry is at the forefront of change. PCBA technology is the driving force behind this transformation. With innovations in PCB automotive design, eco-friendly materials, and smarter electronics, we’re inching closer to a future where vehicles not only reduce emissions but also contribute to a greener, cleaner world. The journey has just begun, but one thing’s for sure: PCBA is steering us in the right direction.