What to Know about NFPA 70E Arc Flash Label Requirements for Workplace Safety

Arc flashes are electrical incidents with the potential to cause severe injuries or even deaths. As electrical energy flows, a fault occurs, energy is released by heat and light, which leads to a fire outbreak, burns, and culminates in several other dangers. It is important to guard employees from similar experiences, especially in any line of work that engages electrical systems.

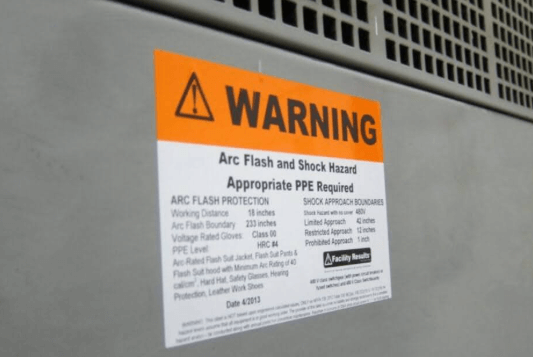

One of the finest precautionary methods to prevent employee injury is the use of arc flash labels, which offer crucial data regarding hazards in an organization. The rules governing the use of labels for electrical equipment are very well defined in the National Fire Protection Association (NFPA) 70E guide. These labels assist workers in understanding the risks they may face at their place of work and show them the precautions they should take.

Tagging electrical panels and facilities shows which arc flash levels can be expected and requires employees to take necessary precautions.

Basic NFPA 70E Arc Flash Label Requirements

NFPA 70E has detailed prescriptions regarding arc flash labeling. These labels should be well-written and placed where workers can easily see them to understand the level of danger they are exposed to, in order to safeguard themselves appropriately. Key elements of the NFPA 70E arc flash label requirements include:

a. Hazard Risk Category (HRC)

The label must contain the hazard risk category that shows the likely degree of an arc flash. This category is most often represented by a set of numbers from zero up to four, with the higher number indicating a higher risk.

b. Incident Energy

It is required that labels state the incident energy level in cal/cm² (calories per square centimeter). This value enables the worker to assess the level of hazard relating to an arc flash, which in turn helps them make the right choice of PPE to wear.

c. Voltage

The label should also include the voltage class, indicating the electrical voltage that may be encountered, so that appropriate security precautions can be taken.

A Compliance Checklist of NFPA 70E Arc Flash Label Requirements

As part of the NFPA 70E arc flash labeling provisions, employers are mandated to perform an arc flash risk analysis. This phase involves studying electrical systems and evaluating the levels of incident energy and the associated risks. The results should inform the crafting of proper and more compliant labels.

It is also necessary to train employees on how to interpret the arc flash labels installed in the facility. In other words, workers must be able to understand the meaning of the labels and how the information on them can help protect them.

Conclusion

NFPA 70E has some imperatives regarding the labeling of arc flash hazards, particularly in areas where electrical risks are present. Through proper and adequately labeled hazard signs, workers can prevent injury and maintain the required safety standards. Some ways that can help the company achieve these objectives include conducting frequent risk assessments and training employees on NFPA 70E.